The IFL PiRo robot detects the objects desired and automatically puts them into shopping baskets.

Credit: Laila Tkotz, KIT

Today, the desired book, toy or household appliance can be purchased by a click only — thanks to online mail order business and smart logistics. The bottleneck in logistics, however, is the high-bay store, where many picking and detection processes cannot yet be executed automatically by robots. At the Amazon Robotics Challenge in Nagoya, Japan, the IFL PiRo team of KIT demonstrated how future warehousing may work. First participation in the international competition was crowned by an excellent 7th place in the overall ranking.

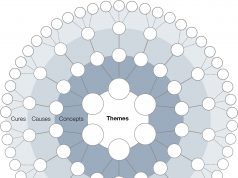

The IFL PiRo team presented with an innovative shelf concept. Instead of arranging the goods in a conventional shelf, the objects are placed in mobile boxes arranged horizontally around the central robot arm. Some of the boxes can be moved by the robot like drawers, thus allowing for a multistorey arrangement. Although load capacity of this system appears to be smaller than that of a shelf system of the same area at first glance, the capacity can be increased easily. In the future warehouse, a second robot might work as a feeder and bring the required boxes or remove those that are no longer needed. “As today’s warehouse systems have reached their technical limits, we wanted to develop a completely new system for the 21st century in order to make full use of the advantages of the robot gripper,” Markert points out. For the video on the system, click: https://youtu.be/3zJ7TLboaUU

The system was designed such that all actions, i.e. detection, picking, suction, dropping, can be carried out with similar movement patterns from above. This facilitates movement planning and execution and makes the movements quicker and more reliable. Moreover, a laser scanner as used in driverless transportation systems can monitor the area above the boxes to control the success of picking, suction, and transport.

To pick the products, the robot uses a gripper or a suction pad. Depending on the product to be picked, the control independently decides on the method to be used and selects the right parameters and contact points. A camera system supplies two- and three-dimensional image information. Using image recognition software and neural networks, the objects are detected. Grip points can be given when teaching the system or calculated from the position and size of the object after object detection.

The IFL PiRo team consists of about 15 students and scientific staff members of the KIT Institute for Materials Handling and Logistics. The team members work in the areas of mechanical engineering, precision engineering/mechatronics, electrical engineering, computer science, and business engineering. Apart from the IFL PiRo system concept and the software, many mechanical parts were self-developed and produced at the own workshop or using 3D printers.

Find your dream job in the space industry. Check our Space Job Board »

Story Source: Materials provided byUniversity of Chicago Original written by Whitney Clavin.Note: Content may be edited for style and length.