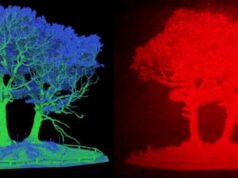

This image shows lignin extraction with (left) and without formaldehyde (right).Credit: Alain Herzog/EPFL

Lignin is a bulky chain of molecules found in wood and is usually discarded during biofuel production. But in a new method by EPFL chemists, the simple addition of formaldehyde could turn it into the main focus.

Reducing our reliance on fossil fuels means turning to plant-derived biofuels and chemicals. But producing them cost-effectively from plants and other organic matter — collectively referred to as biomass — is a major engineering challenge. Most biomass comes in the form of non-edible plants like trees, grass, and algae, which contain sugars that can be fermented to produce fuel. But biomass also contains lignin, a bulky, complex organic polymer that fills wood, bark, and generally gives plants rigidity. Because it is difficult to process, lignin is usually discarded during biofuel processing. EPFL scientists have now turned lignin from a nuisance to an important source of biofuel by simply adding a common chemical, converting up to 80% of it into valuable molecules for biofuel and plastics. The patent-pending method, which can be scaled up to industrial levels, is published in Science.

Complex, but energy-dense

Lignin is an enormously complex biopolymer, filling the hard wall that surrounds each plant cell. In fact, lignin makes up almost a third of plant biomass, and its molecular structure gives it an energy density 30% greater than that of the sugars that are traditionally processed into biofuel. The problem is that lignin is difficult to extract and transform. Due to its instability, lignin usually rapidly gets destroyed during its extraction and most researchers have failed to efficiently break it apart for upgrade into fuels or chemicals.

Now, an international team of researchers led by Jeremy Luterbacher at EPFL, has shown that they can easily break lignin apart simply by adding the chemical formaldehyde to the process. Formaldehyde is one of the most widely used chemicals in industry, and it is simple and cheap to produce. The researchers found that formaldehyde stabilizes lignin and prevents it from degrading, leading to high yields of building blocks that can be used to make substitutes for petrochemicals. These yields were 3-7 times higher than those obtained from lignin without formaldehyde.

Find your dream job in the space industry. Check our Space Job Board »

Scaling up

“Depending on the wood used we get between 50 and 80%,” says Jeremy Luterbacher, who became known in 2014 for developing a method for extracting sugars from plants safely and cheaply (also published in Science). “The chemistry is relatively straightforward; the real challenge is actually finding investors for a pilot facility to demonstrate this.” The market, he says, is difficult for sustainable energy largely because of inconsistent political support and widely varying energy prices. Investors for such innovative platforms are hard to come by in an uncertain market, especially considering the competition of well-established fossil fuels.

“The technology looks really good,” says Luterbacher. “If the global political establishment sent a consistent message about moving away from fossil fuels, then investors would take notice. But I think Switzerland is a great place to get started. The Swiss have been unwavering supporters of clean energy and could help demonstrate new technologies, and so I’m quite optimistic about the future.”

Source: Ecole Polytechnique Fédérale de Lausanne

Research Reference:

Li Shuai, Masoud Talebi Amiri, Ydna M. Questell-Santiago, Florent Héroguel, Yanding Li, Hoon Kim, Richard Meilan, Clint Chapple, John Ralph, Jeremy S. Luterbacher.Formaldehyde stabilization facilitates lignin monomer production during biomass depolymerization. Science, October 2016 DOI: 10.1126/science.aaf7810