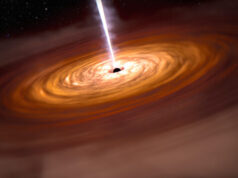

Temperature distribution in an active plasmonic waveguide on an optoelectronic chip with a cooling system

Researchers from MIPT have found a solution to the problem of the overheating of active plasmonic components for high-speed data transfer in the optoelectronic microprocessors of the future. These will be able to function tens of thousands of times faster than the microprocessors currently in use today. In the paper, published in ACS Photonics, the researchers have demonstrated how to efficiently cool optoelectronic chips using industry-standard heatsinks despite the high heat generation in active plasmonic components.

The speed of multicore and manycore microprocessors, which are already used in high-performance computer systems, depends not so much on the speed of an individual core, but rather on the time it takes for data to be transferred between the cores. The electrical copper interconnects used in microprocessors today are fundamentally limited in bandwidth, and cannot maintain the advancement of processor performance. In other words, doubling the number of cores will not double the processing power.

Leading companies in the semiconductor industry, such as IBM, Oracle, Intel, and HP, envision switching from electronics to photonics, and they are currently investing billions of dollars into this. Replacing electrons with photons will mean that large amounts of data can be transferred between processor cores almost instantly, which will mean that the processor performance will be nearly proportional to the number of cores.

Find your dream job in the space industry. Check our Space Job Board »

However, due to diffraction, photonic components are not as easy to scale down as electronic components. Their dimensions cannot be smaller than the size approximately equal to the light wavelength (~1 micrometer or 1000 nanometers), but transistors will soon be as small as 10 nanometers. This fundamental problem can be solved by switching from bulk waves to surface waves, which are known as surface plasmon polaritons (SPPs). This will confine light on the nanoscale. Along with the leading research centers of industrial companies and the laboratories of leading universities, Russian scientists from the Laboratory of Nanooptics and Plasmonics of MIPT’s Center of Nanoscale Optoelectronics are also making good progress in this field.

The main difficulty that scientists face is the fact that SPPs are absorbed by metal, which is a key material in plasmonics. This effect is similar to resistance in electronics, where the energy of electrons is lost and converted into heat when current passes through a resistor. The SPP loss can be compensated by pumping additional energy into the SPPs. However, this pumping will produce additional heat, which in turn will cause an increase in temperature in the plasmonic components and in the processor as a whole. The higher absorption in the metal, the greater the loss, and the stronger pumping will be required. This raises the temperature, which again causes a loss increase and makes it more difficult to create optical gain, which is required to compensate for the loss, and this means that more powerful pumping is required. A cycle is formed in which the temperature can rise to such an extent that a processor chip simply burns out. This is no surprise, since the heating power per surface unit of the active plasmonic waveguide with loss compensation exceeds 10 kW/cm2, which is twice as high as the intensity of solar radiation at the surface of the sun.

Dmitry Fedyanin and Andrey Vyshnevyy, researchers at MIPT’s Laboratory of Nanooptics and Plasmonics, have found a solution to this problem. They have demonstrated that high-performance optoelectronic chips can be cooled with thermal grease—high-performance thermal interfaces consisting of layers of thermally conductive materials placed between the chip and the cooling system.

Based on the results of numerical simulations, Fedyanin and Vyshnevyy concluded that if an optoelectronic chip with active plasmonic waveguides is placed in air, its temperature will increase by several hundred degrees Celsius, which will cause the device to malfunction. Multi-layered thermal interfaces of nano- and micrometer thickness, combined with simple cooling systems, can reduce the temperature of the chip from several hundred degrees to approximately ten degrees with respect to the ambient temperature. This opens the prospects for the implementation of high-performance optoelectronic microprocessors in a wide range of applications, including supercomputers and compact electronic devices.

Source: Moscow Institute of Physics and Technology

Journal Reference:

- Andrey A. Vyshnevyy et al. Self-Heating and Cooling of Active Plasmonic Waveguides, ACS Photonics (2015). DOI: 10.1021/acsphotonics.5b00449