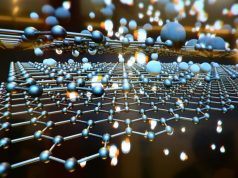

All smart electronics in products such as wrist-wearable computers are on a rigid board under the face of the watch. The roll-to-roll technique enables electronics to be printed on a plastic or elastomeric foil, which has various benefits such as thinness, lightness, elasticity and transparency.

Credit: Antti Veijola

VTT Technical Research Centre of Finland has, for the first time, performed all manufacturing stages for a flexible in-moulded LED foil -in roll-to-roll process. The purpose of this demo is to prove the suitability of the technique for the highly cost-effective manufacture of products such as flexible LED displays containing printed electronics.

“For the wristband demo, we performed all of the key manufacturing stages for printed hybrid systems — the printing of conductors, the assembly of semiconductor LEDs and the overmolding — using the roll-to-roll technique. This enables the mass manufacture of small-sized, easy-to-use, flexible electronics in a cost-effective manner,” says Sami Ihme, Senior Scientist.

In practice, the roll-to-roll overmolding of a printed electronic foil involves feeding a LED foil with a foilfeeder into a mould, in which the overmolding is done. This technique is normally used to decorate plastic for various consumer products. However, the manufacture of flexible electronics — in place of graphics — involves feeding electronics with a range of electrical and optical features into a mould.

Companies invited to create new products

Find your dream job in the space industry. Check our Space Job Board »

“The results have been promising. In the first test run for the overmolding of 186 LEDs, we achieved a 100% yield,” explains Ihme.

VTT Technical Research Centre of Finland Ltd is now seeking product companies interested in trying this new technology, in order to create new product concepts for the markets.

The demo will be presented at the international LOPEC fair for printed electronics in Munich, Germany on 29-30 March.