Semiconductors, which are the basic building blocks of transistors, microprocessors, lasers, and LEDs, have driven advances in computing, memory, communications, and lighting technologies since the mid-20th century. Recently discovered two-dimensional materials, which feature many superlative properties, have the potential to advance these technologies, but creating 2-D devices with both good electrical contacts and stable performance has proved challenging.

Researchers at Columbia Engineering report that they have demonstrated a nearly ideal transistor made from a two-dimensional (2-D) material stack—with only a two-atom-thick semiconducting layer—by developing a completely clean and damage-free fabrication process. Their method shows vastly improved performance compared to 2-D semiconductors fabricated with a conventional process, and could provide a scalable platform for creating ultra-clean devices in the future. The study was published today in Nature Electronics.

“Making devices out of 2-D materials is a messy business,” says James Teherani, assistant professor of electrical engineering. “Devices vary wildly from run to run and often degrade so fast that you see performance diminish while you’re still measuring them.”

Having grown tired of the inconsistent results, Teherani’s team set out to develop a better way to make stable devices. “So,” he explains, “we decided to separate the pristine device from the dirty fabrication processes that lead to variability.”

As shown in this new study, Teherani and his colleagues developed a two-step, ultra-clean nanofabrication process that separates the “messy” steps of fabrication—those that involve “dirty” metallization, chemicals, and polymers used to form electrical connections to the device—from the active semiconductor layer. Once they complete the messy fabrication, they could pick up the contacts and transfer them onto the clean active device layer, preserving the integrity of both layers.

Find your dream job in the space industry. Check our Space Job Board »

“The thinness of these semiconductors is a blessing and a curse,” says Teherani. “While the thinness allows them to be transparent and to be picked up and placed wherever you want them, the thinness also means there’s nearly zero volume—the device is almost entirely surface. Because of this, any surface dirt or contamination will really degrade a device.”

Currently, most devices are not encapsulated with a layer that protects the surface and contacts from contamination during fabrication. Teherani’s team showed that their method can now not only protect the semiconductor layer so that they don’t see performance degradation over time, but it can also yield high performance devices.

Now that the researchers have developed a stable, repeatable process, they are using the platform to make devices that can move out of the lab into real-world engineering problems.

“The development of high performance 2-D devices requires advances in the semiconductor materials from which they are made,” Teherani adds. “More precise tools like ours will enable us to build more complex structures with potentially greater functionality and better performance.”

The study is titled “Transferred via contacts as a platform for ideal two-dimensional transistors.”

Provided by: Columbia University School of Engineering and Applied Science

More information: Younghun Jung et al. Transferred via contacts as a platform for ideal two-dimensional transistors. Nature Electronics (2019). DOI: 10.1038/s41928-019-0245-y

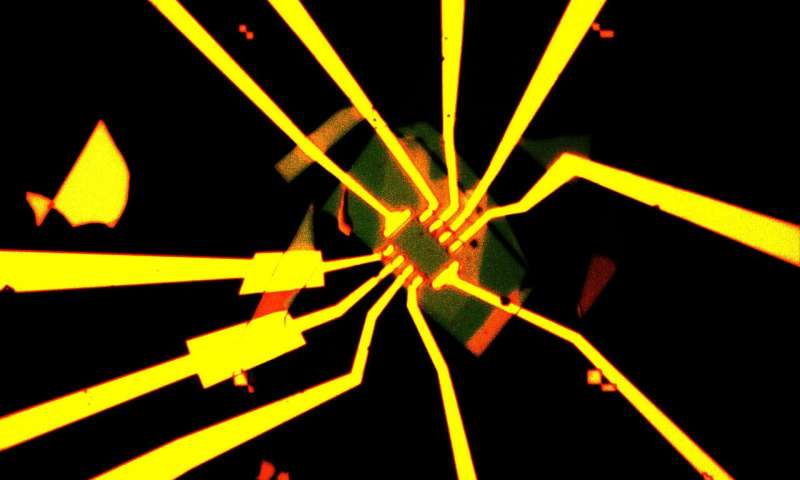

Image: An enhanced optical microscope image of a Hall-bar structure used to characterize transistor properties for devices made with ultraclean transferred contacts. The long radial lines, made from deposited gold, connect the small contacts at the center of the device to large probe pads for easy measurements.

Credit: Min Sup Choi/Columbia Engineering