In a feat requiring perseverance, world-leading technology, and no small amount of caution, scientists have used intense X-rays to inspect irradiated nuclear fuel. The imaging, led by researchers at Purdue University and conducted at the U.S. Department of Energy’s (DOE) Argonne National Laboratory, revealed a 3-D view of the fuel’s interior structure, laying the groundwork for better nuclear fuel designs and models.

Until now, examinations of uranium fuel have been limited to mostly surface microscopy or to various characterization techniques using mock versions that possess little radioactivity. But scientists want to know at a deeper level how the material changes as it undergoes fission inside a nuclear reactor. The resulting insights from this study, which the Journal of Nuclear Materials published in August 2020, can lead to nuclear fuels that function more efficiently and cost less to develop.

To get an interior view of the uranium-zirconium fuel studied, the researchers sectioned off a bit of used fuel small enough to be handled safely—a capability developed only within the last seven years. Then, to see inside this tiny metallic sample, they turned to the Advanced Photon Source (APS), a DOE Office of Science User Facility located at Argonne.

A study decades in the making

Before the researchers could approach the formidable task of isolating a fuel sample and placing it under an X-ray beam, they needed to find the right specimen. Exploring fuels archived at DOE’s Idaho National Laboratory (INL), they identified a uranium-zirconium fuel that spent a total of two years at full power in the Fast Flux Test Facility in Hanford, Washington, and was removed from the reactor in the early 1990s.

Find your dream job in the space industry. Check our Space Job Board »

“We had to wait decades for this fuel to radiologically cool or decay,” said Maria Okuniewski, assistant professor of materials engineering at Purdue University and the paper’s lead author. “It was literally the coolest specimen that we could remove based on the permissible safety guidelines at both INL and APS.”

Even the coolest available spent fuel specimen was still too hot, radiologically speaking, at its original size. Taken from a larger fuel pin, the sample was less than a quarter of an inch high, but it measured 1,200 millirem per hour from a distance of 30 centimeters—a radiation level 240 times larger than the allowable limit at the APS.

To reduce the radioactivity, the researchers used a focused ion beam with scanning electron microscopy at INL to create a much smaller sample. The tool allowed them to pinpoint an area of interest and deploy a stream of ions that essentially milled out a cube of material. The resulting sample was roughly 100 microns across, no larger than the diameter of a human hair.

“We’ve come a long way with this new instrumentation that allows us to obtain samples that are small enough to be safe and easily handled,” said Okuniewski.

The miniscule sample was mounted on a pin, encased in a double-walled tube, and sent to Argonne, with multiple radiation checks to ensure safety along the way.

At Argonne, the Purdue research team worked with scientists at beamline 1-ID-E, a high-brilliance X-ray source at the APS, to examine the sample. The goal: To see what uranium-zirconium fuel looks like on the inside after it has been bombarded with neutrons for two years.

“We are really talking about a piece of dust that you can barely see with the naked eye—it’s that small,” said Peter Kenesei, a physicist with Argonne’s X-ray Science Division and study co-author. “But this is also very dense material, so you need a sufficient intensity of high-energy X-rays to penetrate and study it.”

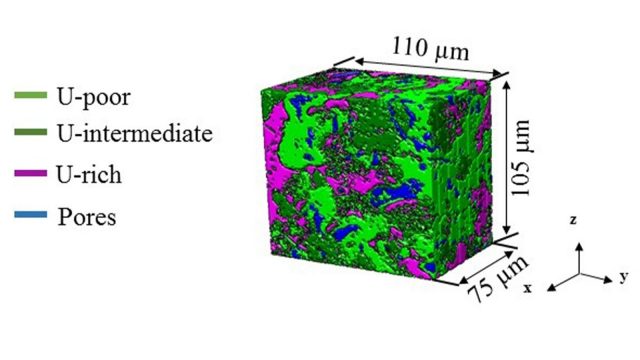

The technique used, micro-computed tomography, detects at high resolution the X-ray beam as it emerges on the other side of the sample. From multiple images taken as the fuel was rotated, computers could reconstruct its internal features based on how it altered the incoming beam, similar to a medical CT scan.

“The 1-ID-E beamline’s flexibility, along with Argonne’s expertise in safely handling nuclear materials, allows us to design and conduct a unique experiment like this one,” Kenesei said.

Closer look at fuel swelling

In particular, Okuniewski and her colleagues were interested in the phenomenon of swelling. Nuclear fuel generates energy by taking one uranium atom and splitting it into two, and this fission process generates byproducts such as the gas xenon and metals like palladium and neodymium. As atoms split and fission products accumulate, the fuel grows in volume.

The safety and longevity of any given nuclear fuel depends on being able to predict how much it will swell. Too much swelling can cause the uranium to react with, and possibly fracture, its protective outer layer, called a cladding. To prevent that from happening, engineers rely on fuel performance codes, which are computer models that simulate various aspects of a fuel’s behavior in a reactor, such as how hot in temperature it will get and how its constituents redistribute in space.

“In every single fuel type, swelling is an issue,” Okuniewski said. “These fuels are designed so that the inner core is free to expand to a specific level before it touches the cladding.”

In addition to providing a clearer, localized picture of the fuel structure and the different material phases that developed over time, the study at the APS revealed evidence that the release of fission gases might continue to occur beyond the thresholds assumed in previous analyses. This type of data can help strengthen fuel performance codes, which in turn would help lower the cost of fuel development, since reliable computer simulations can minimize the number of expensive irradiation tests needed.

“We’re always striving within the nuclear community to figure out ways that we can improve the fuel performance codes,” Okuniewski said. “This is one way to do that. Now we have three-dimensional insight that we previously didn’t have at all.”

Provided by: Argonne National Laboratory

More information: Jonova Thomas et al. The application of synchrotron micro-computed tomography to characterize the three-dimensional microstructure in irradiated nuclear fuel. Journal of Nuclear Materials (2020). DOI: 10.1016/j.jnucmat.2020.152161

Image: 3-D image reconstruction of a sample of irradiated fuel, showing the three thresholded uranium phases co-existing with pores.

Credit: Maria Okuniewski / Purdue University